Table of Contents

Introduction

Contract manufacturers face constant pressure—tight production schedules, multiple clients, cost control, and quality assurance. Staying competitive requires more than effort; it demands the right technology. NetSuite Contract Manufacturing is designed to handle these complexities, providing real-time insights, automation, and streamlined workflows.

From managing production and coordinating suppliers to tracking inventory across locations, NetSuite manufacturing solutions help reduce errors, improve margins, and drive efficiency. Whether you’re optimizing the contract manufacturing process with NetSuite or leveraging its automation capabilities, the platform ensures smooth operations.

This blog explores how NetSuite enables manufacturers to scale operations, meet client demands, and improve overall process control.

Overview of Contract Manufacturing

Contract manufacturing is an outsourced production model where a company partners with a manufacturer to produce goods based on agreed specifications. Depending on the contract, the buyer may supply materials entirely, partially, or not at all. Managing these operations efficiently is crucial to maintaining profitability, quality, and compliance.

Key challenges in contract manufacturing include:

- Make-to-Order Production – Managing demand-driven workflows.

- Custom Manufacturing – Adapting to unique client specifications.

- Traceability – Tracking materials, components, and finished goods.

- Complex Multi-Stage Processes – Coordinating multiple production phases.

- Integrated Manufacturing – Aligning vertical production flows.

- Quality Control and Compliance – Ensuring regulatory and industry standards.

- Logistics and Shipping – Managing fulfillment and distribution.

- Intellectual Property Protection – Safeguarding confidential designs and processes.

- Cost Control – Optimizing expenses without compromising quality.

A robust NetSuite manufacturing module helps contract manufacturers address these challenges by providing automation, real-time visibility, and streamlined workflows. With NetSuite Outsourced Manufacturing, businesses can enhance traceability, improve supply chain coordination, and ensure compliance while maintaining cost efficiency.

What Is NetSuite Contract Manufacturing?

NetSuite Contract Manufacturing enables users to manage the entire lifecycle of contract manufacturing, along with flexibility from production planning to materials requirement planning, inventory management, and invoicing in an automated and effective way in a single unified platform.

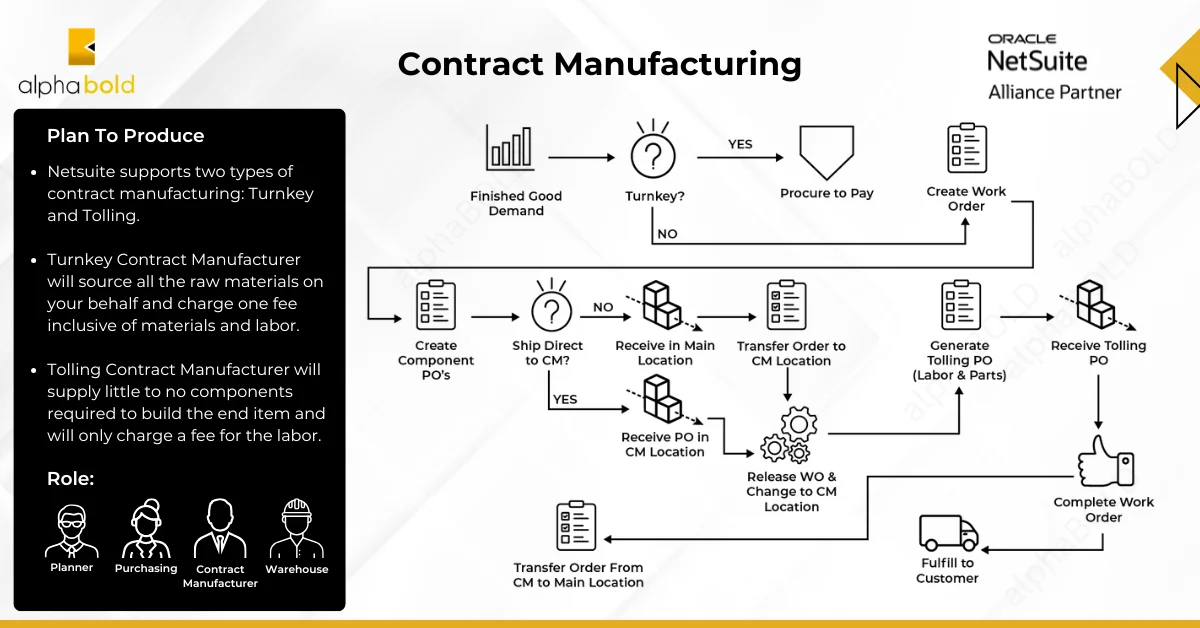

NetSuite Manufacturing consists of the following types:

- Turnkey – Contract Manufacturing

- Tolling – Contract Manufacturing

NetSuite Contract Manufacturing Process Flow:

NetSuite Contract Manufacturing features automate the following processes:

- Automates creating purchase orders for contract manufacturing directly from work orders.

- Automates creating work orders for contract manufacturing directly from purchase orders if the process is initiated from the purchase order.

- Automates creating sub-assemblies work orders to be outsourced.

- Drop shipping functionality provides finished goods to be shipped and dispatched directly from third-party contractor locations, eliminating manual transfers.

Read More: NetSuite Advanced Manufacturing: Key Modules and Benefits.

NetSuite Contract Manufacturing: Key Features and Benefits

1. Planning and Forecasting:

The demand and planning feature allows for successful production planning by scheduling the orders, meeting the customer objectives, and ensuring confidence in lead times for products, sub-assemblies, and NetSuite contract manufacturing processes. It integrates Material Requirements Planning (MRP) and Warehouse Management System (WMS) operations to enhance efficiency.

The ERP leverages infinite capacity scheduling with WIP and routing and finite capacity scheduling with advanced manufacturing to plan and forecast orders for order-based manufacturing, order-to-stock, or contract manufacturing by setting the manufacturing capacity for each and individual contract manufacturer.

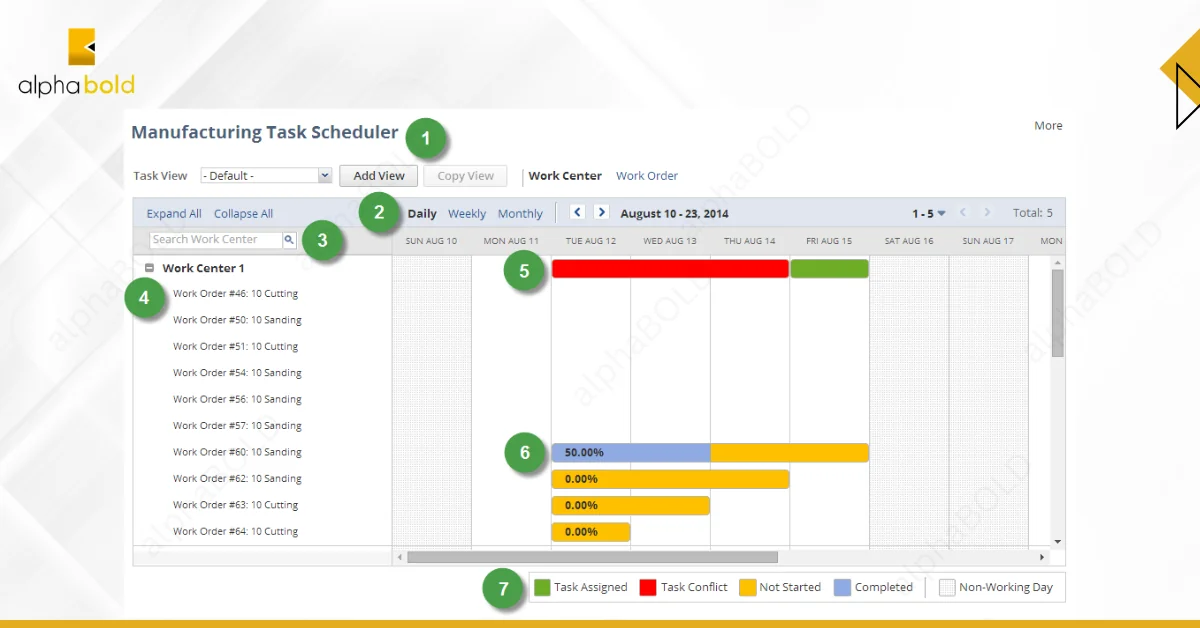

NetSuite’s planning engine provides real-time insights along with the help of the Manufacturing Task Scheduler for successfully scheduling and executing the manufacturing cycle run efficiently and effectively, which will result in reducing downtime and increasing efficiency.

2. NetSuite Enterprise Performance Management (EPM):

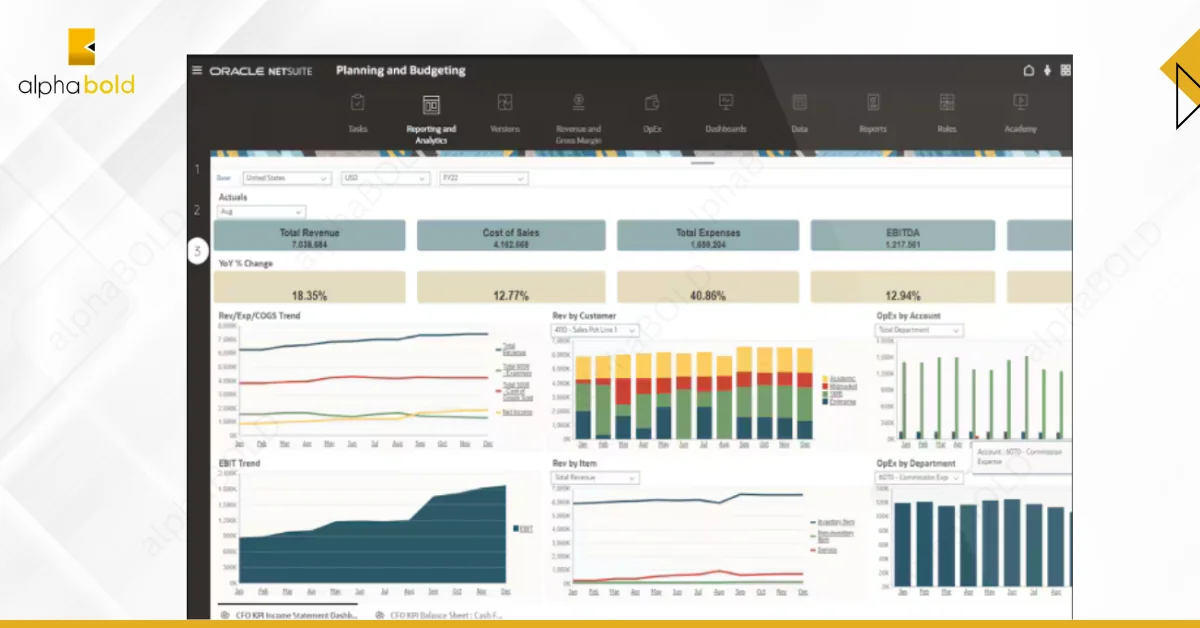

NetSuite’s EPM system is a comprehensive tool for budgeting and planning that amalgamates strategies into the operations to have a better understanding and results of the organizational performances to improvise accordingly.

EPM Budgeting can automate labor planning with predefined rules and generate operational reports to have better insights, along with AI and machine learning models for automation of data analysis to improve accelerated planning and forecasting.

3. Streamlined Supply Chain Management:

NetSuite’s Advanced Order Management transforms complex supply chain operations into streamlined, automated processes through a unified, integrated platform. From handling customized orders to ensuring traceability and risk management, NetSuite equips manufacturers with the tools to optimize efficiency and reduce operational challenges.

- Automated Order Allocation: Simplify order fulfillment with intelligent, rule-based scheduling and delivery commitments—even for contract manufacturers using drop-shipping.

- Intelligent Order Orchestration: Enhance customer satisfaction by selecting the most efficient delivery locations, minimizing shipping times and costs.

- Risk Management and Control: Maintain optimal inventory levels with customizable controls for items and locations, ensuring smooth operations across diverse business scenarios.

The Ship Central feature can extend label printing functionality to set different labels for shipment, returns, and hazardous materials for better customer experiences and different labels for manufacturers for better traceability. This feature provides Weighing Scale Support and Tare Weight for Pallets.

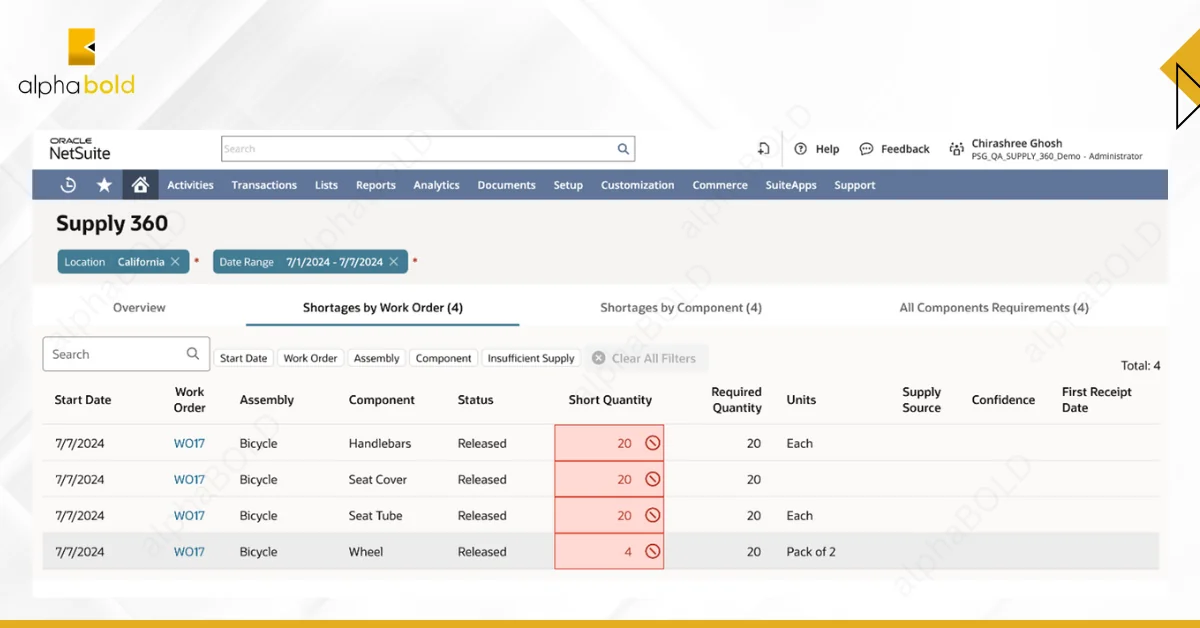

NetSuite provides real-time visibility of the stocks with multiple analytical views designed for different relevant roles. This is crucial for traceability, particularly for vertically integrated manufacturing systems and outsourcing processes. Real-time costing and decision-making are very important, especially for custom-tailor or order-based manufacturing.

Explore How You Can Enhance Your Netsuite System Through Customizations: Maximizing NetSuite Through Customizations: A User’s Guide for 2025.

4. Material Requirement Planning - MRP:

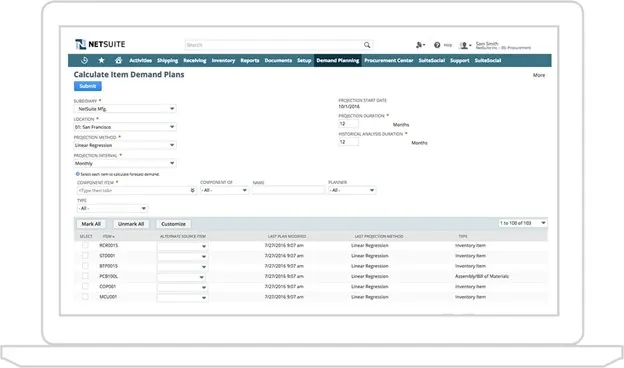

MRP is a comprehensive functionality of NetSuite Manufacturing that generates the supply plans (Work Orders (WO), Transfer Orders, and Purchase Orders (PO)) compared to the actual demand and optimum levels of the stocks, that materials or goods should be available on a certain date which implies that a certain process should be started at a particular date and resources should be available for further processing or outsourcing.

MRP automates the creation of NetSuite contract manufacturing WOs, transfer orders, and materials planning for transfer to the contract manufacturer location. Contract manufacturing planning and processes are automated so that management can focus on innovation and develop new products.

5. Available Materials to Manufacture and Plan:

Available to Build (ATB) is a SuiteApp feature users can leverage to evaluate and plan how many quantities of finished goods or assemblies can be manufactured based upon the current availability of the materials. This feature allows the evaluation of the final assembly and quantities of sub-assemblies or semi-finished items and provisioning to determine the capacity in days that can be utilized. The manufacturing cycle can continue to run to support sales forecasts to have in-depth analysis before the materials get short or out of the market.

Struggling with the complexities of contract manufacturing?

AlphaBOLD’s NetSuite experts are here to help! Request a demo today to see how we can customize NetSuite to solve your unique challenges—from managing multiple suppliers to optimizing production scheduling. Let’s work together to build a solution that scales as your business grows.

Request a Consultation6. Quality Management:

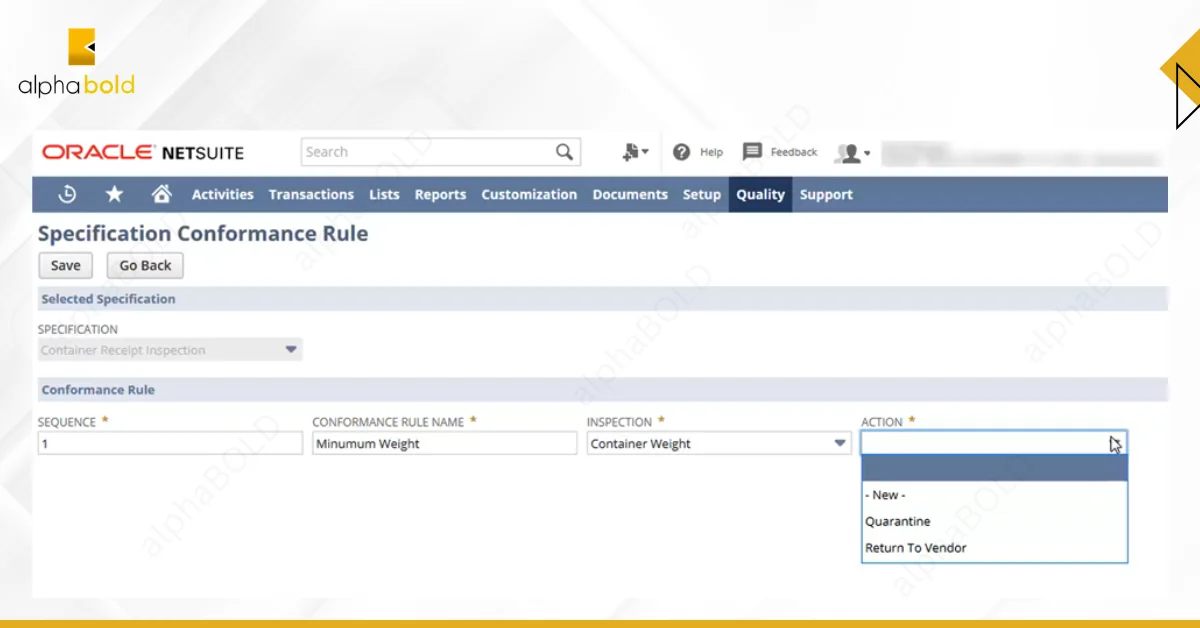

As we know, one of the key challenges with outsourcing is ensuring quality control. NetSuite’s Quality Management SuiteApp is a comprehensive solution where you can design predefined criteria such as inspections and specifications. Specifications can be assigned to the items, vendors, locations, and work center or production stages to trigger the quality tests automatically.

NetSuite’s conformance rules play a significant role in establishing controls and automating returning the goods to the vendor if they fail the inspection. The item that has been rejected as per the conformance rule’s criteria of “Quarantine” will be unavailable temporarily if the inspection fails.

NetSuite leverages the ability to define different tests for the same item for different manufacturers and frequencies for each vendor. NetSuite also provides enough flexibility to perform any inspection at any time with the feature of Ad-Hoc quality inspection. It also allows for custom workflows to be designed.

The NetSuite Quality Management Suite App is incredibly important to ensure compliance and safety standards, particularly regarding outsourcing manufacturing. It also provides the ability to integrate with third-party tools to capture results.

7. NetSuite Vendor-Sourcing Management:

NetSuite Sourcing Management software lets you find the vendors with the desired quality and specification of goods at competitive prices as a global reach to the vendors. This feature allows you to streamline and simplify the process by sharing the same Request for Quotes (RFQs) and details across all the vendors to receive bids on the same platform, ensure transparency, and perform analysis of different proposals.

This feature manages the complete exchange of information with vendors in a single location once the vendor is finalized. This feature minimizes the chances of errors, increases efficiency, and solidifies the relations with vendors because they have the same platform. These documents can also be used as a reference for future proposals.

8. NetSuite CRM Upsell Manager:

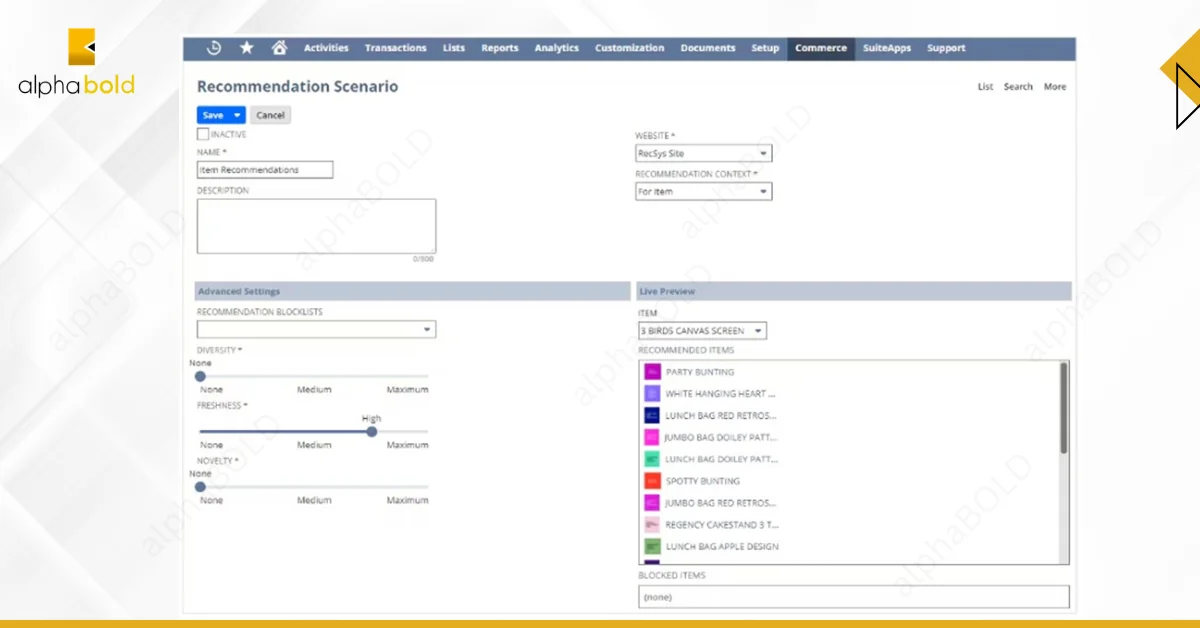

NetSuite’s CRM upselling feature can elevate the marketing and sales revenues by having AI-based algorithms called Intelligent Recommendations suggest the line of products on the documents of “Opportunity,” “Quotations,” and “Sales Order” for the sales representative along with the suggestions for the different areas of the suite-commerce website which can be earmarked for the relevant customers. This feature forages past transactions and suggests the appropriate items and line of items based on their correlation, making it enticing for the customers. This can play an important role in planning and forecasting with improved supply chain operations, production planning, and contract manufacturing.

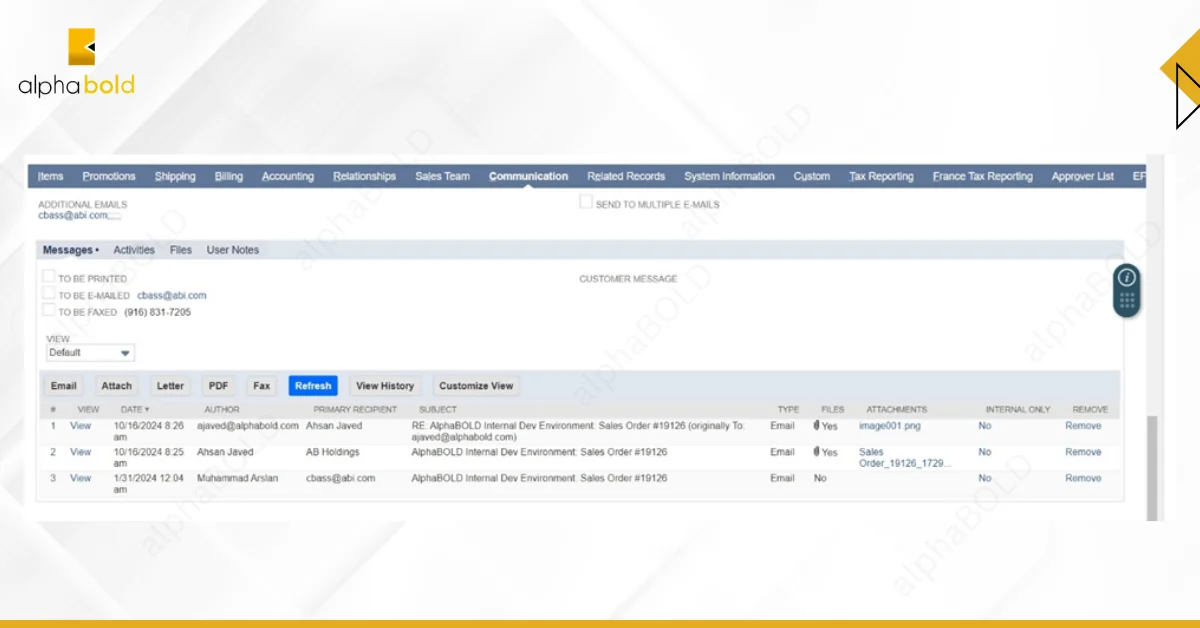

9. Communication with Business Partners:

NetSuite extends the functionality to collaborate with your customers, vendors, and other business partners by sending the documents and updates related to the orders directly from NetSuite and receiving back the responses. This feature simplifies communication with outsourcing vendors along with greater traceability because it becomes complex when rework is required especially in contract manufacturing and outsourcing. Therefore, all the details shared with vendors are readily available with each relevant transaction.

It increases transparency, minimizes the chances of errors, and provides the traceability of the communication and traceability related to the data. It also reduces confidentiality issues as essential documents will not need to be downloaded or sent separately.

Bonus Insights: 10 Signs Your NetSuite ERP Needs Optimization Now.

10. Flexibility:

NetSuite allows semi-finished goods to be relocated to any other contract manufacturer location in real-time with complete costing and traceability available. More than one Bill of Materials (BOM)can be created for an assembly item to analyze the impact of quality and cost differences when using similar materials.

Revisions of a BOM can also be created to compare with the previous versions. Multiple routings can be created for an assembly item, allowing different operations in different manufacturing locations. Separate locations are defined for outsourcing vendors separately, allowing for better traceability.

Workflows can be customized to allow flexibility and automation. As a leading cloud-based ERP solution, NetSuite offers seamless scalability, enabling your business to efficiently expand operations and enter new markets.

The Manufacturing Task Scheduler offers a flexible solution for managing work orders. It enables you to reassign tasks from overloaded work centers to available dates or other work centers using a simple drag-and-drop interface. These adjustments are automatically reflected in the corresponding work order documents, ensuring real-time updates and seamless integration across your scheduling and operational systems.

Curious About How NetSuite Can Transform Your Operations?

Let us show you the power of an optimized ERP solution for contract manufacturing. AlphaBOLD’s team of experts will help you unlock the full potential of NetSuite, from automating processes to streamlining communication with vendors. Schedule your call now and take the first step towards a more efficient and scalable future.

Request a Call with Our TeamConclusion

Implementing NetSuite Contract Manufacturing can transform your contract manufacturing business. To fully realize its potential, having the right partner by your side makes all the difference. That’s where AlphaBOLD excels. As an experienced NetSuite Alliance Partner, we don’t just help you get set up—we tailor NetSuite to your unique business needs and ensure you’re fully equipped to maximize its benefits.

We understand the complexities of contract manufacturing. Whether you’re managing multiple suppliers, balancing inventory, or facing tight production timelines, our team is here to help you navigate those challenges with a customized NetSuite system that works best for you. From initial implementation and system configuration to training and ongoing support, we’re committed to being your trusted partner every step of the way.

Explore Recent Blog Posts